How To Drill Brake Discs

Welcome to an enlightening journey into the world of automotive maintenance! In this article, we will delve into the intricate process of drilling brake discs, uncovering the fascinating reasons, methods, and benefits behind this practice. Whether you're a seasoned car enthusiast seeking to elevate your braking performance or simply curious about the inner workings of your vehicle, join us as we explore the art of transforming ordinary brake discs into extraordinary components. Prepare to be captivated by the science, safety, and engineering prowess that go into this meticulous procedure. Get ready to discover how drilling brake discs can revolutionize your driving experience and give you unparalleled confidence on the road.

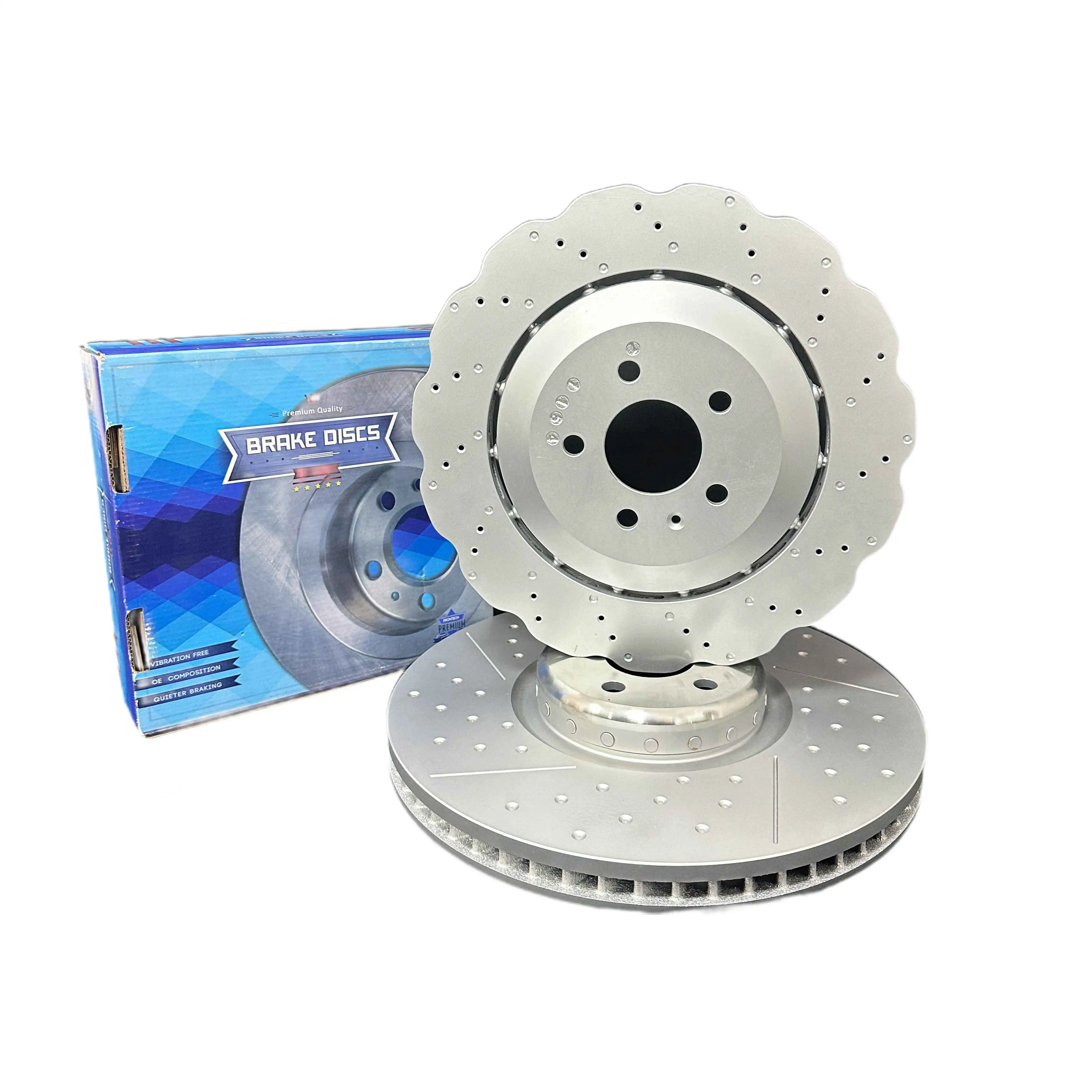

Understanding the Benefits of Drilled Brake Discs

Frontech Auto Parts, a leading manufacturer in the automotive industry, has revolutionized brake disc technology with their innovative approach. In this article, we will explore why drilling brake discs can enhance both the performance and safety of your vehicle.

Unleashing the Power of Frontech Drilled Brake Discs

When it comes to brakes, the ability to quickly and efficiently dissipate heat is crucial. Frontech Auto Parts understands this necessity and offers drilled brake discs that provide exceptional heat management. By strategically drilling holes into the brake discs, Frontech enables increased heat dissipation, reducing the risk of brake fade and enhancing overall stopping power.

Enhanced Cooling for Superior Performance

One of the primary advantages of drilled brake discs is their ability to maintain lower operating temperatures. The holes created by Frontech Auto Parts in their brake discs facilitate increased airflow, promoting rapid cooling and preventing overheating during demanding driving conditions. This enhanced cooling not only preserves the longevity of the brakes but also improves their performance, ensuring consistent and reliable stopping power.

Reduced Brake Pad Glazing and Increased Pad Life

Frontech Auto Parts' drilled brake discs also address the common issue of brake pad glazing. When brake pads become excessively heated, a layer of glazed material can form on their surface, impairing their ability to grip the rotor effectively. By allowing heat to escape through the drilled holes, Frontech braked discs minimize pad glazing, leading to improved pad life and reducing the need for frequent replacements.

Safety First: Enhanced Wet Weather Performance

Driving in wet conditions presents an added challenge as water can hinder braking efficiency by creating a film between the brake pads and rotor. Through the drilling process, Frontech Auto Parts crafted brake discs that efficiently channel water away, reducing the risk of hydroplaning and improving overall wet weather performance. The drilled holes in the disc also serve as an escape route for water and any other debris that may accumulate on the brake surface, ensuring consistent contact between the pads and discs for optimal braking power.

In conclusion, Frontech Auto Parts has made significant advancements in brake disc technology by introducing drilling techniques to enhance performance and safety. Their range of drilled brake discs effectively dissipates heat, reduces glazing, prolongs brake pad life, and improves wet weather performance. So, if you are looking to take your vehicle's braking capabilities to the next level, consider Frontech Auto Parts as the go-to option for drilled brake discs that combine innovation, quality, and safety.

Conclusion

In conclusion, drilling brake discs is a technique that can greatly enhance the performance and safety of your vehicle. From a performance standpoint, drilling helps dissipate heat effectively, preventing brake fade and maintaining consistent braking power. Additionally, it allows for better water and debris dispersion, improving the overall efficiency of your brakes. From a safety standpoint, drilled brake discs can reduce the risk of brake glazing and minimize the chances of hydroplaning in wet conditions. However, it is crucial to keep in mind that proper drilling techniques, precise measurements, and high-quality equipment are vital to ensure optimal results. By following the steps outlined in this article, you can confidently drill your brake discs, knowing that you are enhancing both the performance and safety of your vehicle. So, don't hesitate to give it a try and experience the difference it can make on your next drive. Safe and enjoyable driving!